SPROCKET ORDERING INFORMATION:

Standard Chains

When Ordering Sprockets For Standard Chains Please Specify:

- Chain Size (number marked on barrel or side bar)

- Number of teeth required

- Bore, keyseat, setscrew

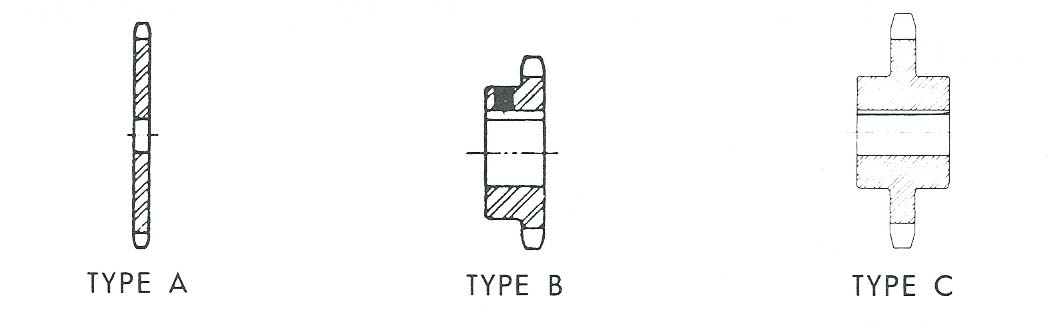

- Hub Type (B or C) see below for minimum standard sizes

- Harness required (Rockwell C 30-35 is harness as flame cut. Rockwell C 47-55 is achieved with standard heat treating)

- Is sprocket one-piece or of split construction

- Is bronze bushed bore required

- If Type A plate-type sprocket (no hub), specify: - center hole; bolt circle: number and size of bolt holes.

- If minimum plain bore (stock bore) is required, specify ultimate or maximum bore required

- Any special tooth contour (please supply print)

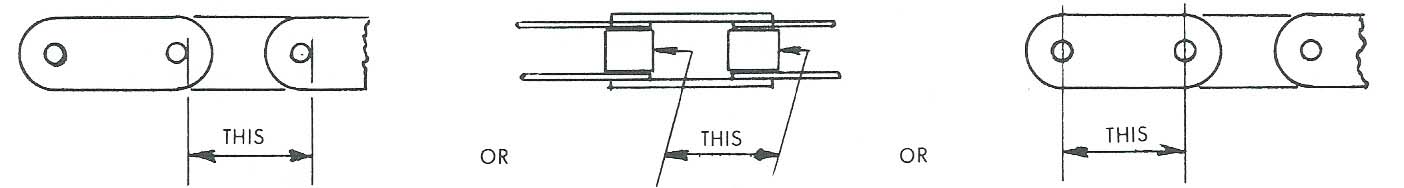

Pitch Diameter and Plate Thickness

To Determine Pitch Diameter and Plate Thickness When Not Known

- To determine sprocket pitch diameter, multiply chain pitch by tooth constant shown in the table below. For Skip Tooth sprockets or Traction Wheels, use number of chain pitches on pitch diameter and not number of teeth.

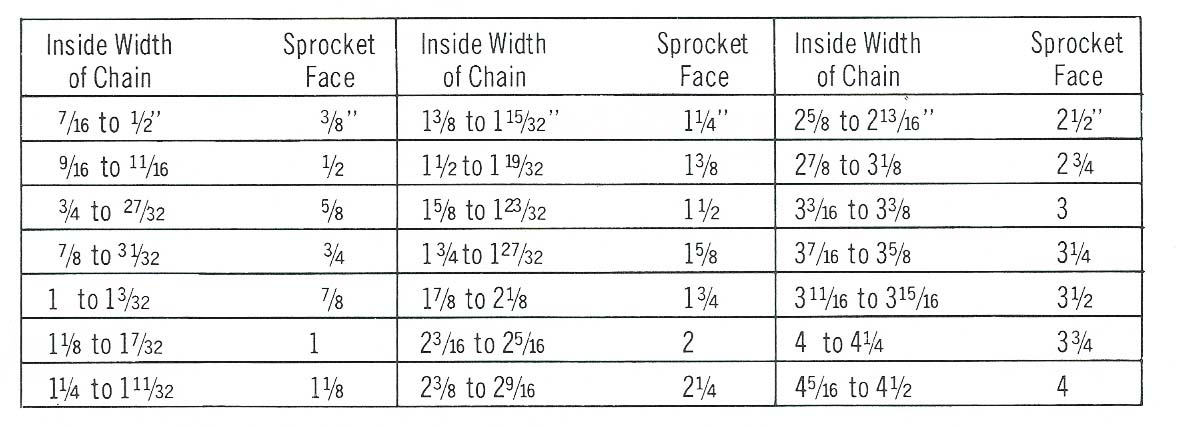

2. Determine plate thickness from table and sketches below

Standard Tooth Thickness

Sprockets For Special Chains

- In addition to all of the above information, it is necessary to determine pitch of chain

- Measure roller diameter. If badly worn, try to determine original size

- Measure height of chain side bar

- Is there an O.D. interference with chain attachments, guards, etc?

Are there rods or bars thru chain sidebars between the rollers? If so, please locate and list size of thru rods.

Types of Sprockets

Double Duty sprockets have two teeth for each pitch so when one set of teeth is worn the chain can be advanced one half pitch to a new set of teeth. Often used with long pitch chains. These are similar to Hunting Tooth sprockets.

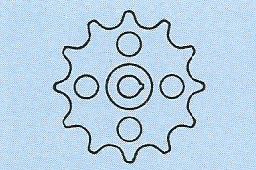

Hunting Tooth sprockets have an odd number of teeth with the pitch of the teeth one-half of the chain pitch. This causes the chain roller to advance one half pitch for each revolution, doubling the number of contacts and doubling the sprocket life.

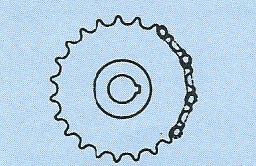

Skip Tooth sprockets have a pitch diameter with an even number of chain pitches with a tooth omitted at every other pitch. To figure the pitch diameter use twice the number of teeth. Drop - forged chains require this type of sprocket because of there solid “roller link”.

Gap Tooth sprockets are used with chains having through rods or rollers located between the chain pin rollers that articulate over the sprocket. clearance in the tooth form is provided for these rods.

Draw Bench chains often have alternate pitches of different lengths and are skip tooth design, when “roller” link is solid bar. The higher tensile of steel sprockets is advantageous.

Segmental Rim sprockets have a bolt-on rims in 3, 4 or more pieces. The sprocket rim can be replaced without removing the chain from the sprocket or the sprocket from the shaft. This type is ideal for elevators. The hubs can be made in solid or split construction.

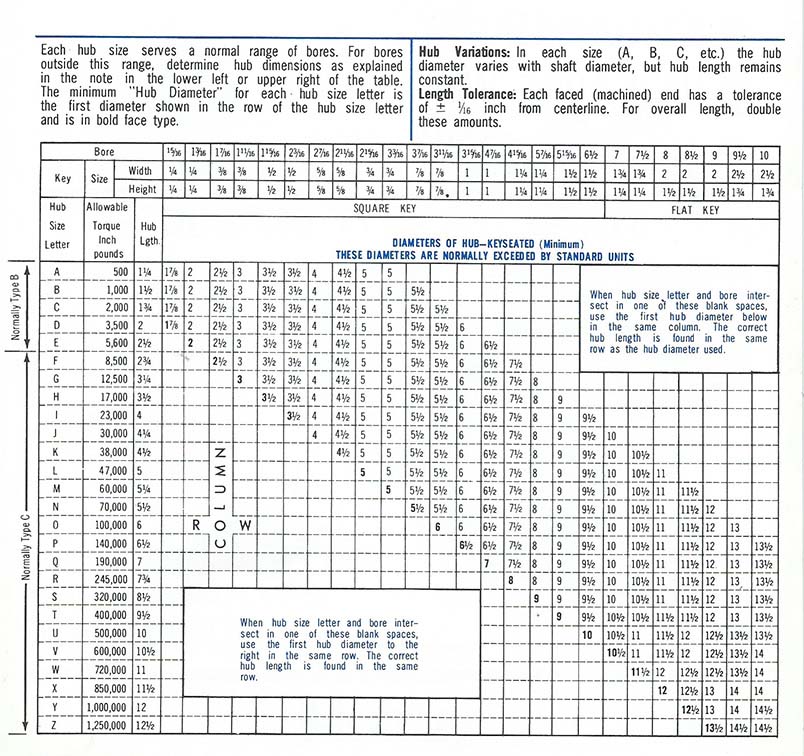

Standard Hub Sizes

Fabricated Steel

TORK-TROL Sprocket Sizes & Shear Pin Ratings

TORK-TROL Selection Procedure

Hub and Sprocket Size

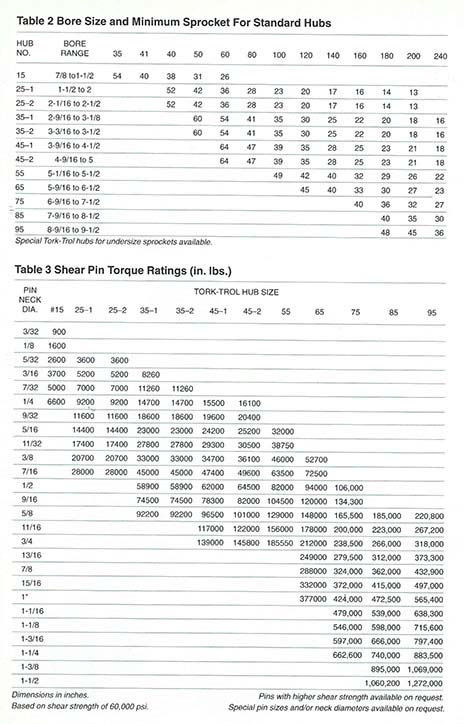

Hub size and he minimum number of teeth on the sprocket it carries are both related to shaft diameter. Refer to Table 2 to select the proper Tork-Trol hub to fit your shaft size, and then read the minimum number of teeth required on your roller chain sprocket, for that hub. If your sprocket has the minimum number of teeth or more, proceed with the torque and pin neck diameter calculations below.

If your application involves a sprocket with fewer teeth than the minimum indicted in Table 2, ABC Murray Sprockets can provide a special Tork-Trol hub designed to accommodate it. Other hub modifications are also possible to meet special needs. Call our engineering department (800) 272-0354 for assistance.

Torque Load and Pin Neck Diameter

Use one of the three methods listed below to determine the torque load on the hub. Once the load is known, consult Table 3 and select an appropriate shear-pin neck diameter to carry it.

Symbols

| T | Torque in inch pounds | |||

| HP | Horsepower at the sprocket | |||

| RPM | Sprocket revolutions per minute | |||

| R | Sprocket pitch radius | |||

| CP | Chain pull in pounds | |||

| 1.5 | Starting load factor |

These are examples below

Method A

When reducer output torque and drive speed ratio are known

| T= | Output Torque X | |||

| Drive Speed Ratio X 1.5 |

Method B

When horsepower at sprocket and sprocket RPM are known.

| T= | HP X 63000 X 1.5 | |

| RPM |

Method C

When chain pull and sprocket pitch radius are known

T= CP X R X 1.5

Selection Example

Select a Tork-Trol assembly for a conveyor chain drive:

Conveyor Requirements: Head Shaft requires 5 HP at 22.8 RPM, with 1925 lbs. chain pull. Conveyor sprocket pitch diameter is 14.334 in. and Head Shaft diameter is 2-7/16".

Drive Specifications: Motor; Reducer with 4600 in. lbs. torque output; and 3:1 ratio chain drive consisting of RC80, 15 tooth and RC80 45-tooth sprockets. (Pitch diameter of RC80A45 sprocket is 13.334 in.)

Hub & Sprocket Size

Refer to Tables Below 2: A#25-2 Tork-Trol hub will fit the 2-7/16i". diameter head shaft. The RC80A45 sprocket will fit the 25-2 hub and has more than the minimum number (28) of teeth.

Find Torque Load and Pin Neck Diameter.

Method A

| Known: | Speed reducer output torque | ||

| (4600 in. lbs.) | |||

| Speed ratio of chain drive | |||

| (3:1) | |||

| T = 4600 X 45 X 1.5 = 20,700 IN. LBS. | |||

| 15 |

Method B

| Known: | Head shaft HP (5) | |

| Sprocket RPM (22.8) | ||

| T = 5 X 6300 X 1.5 = 20,700 IN. LBS | ||

| 22.8 | ||

Method C

| Known: | Chain pull (1925 lbs.) | |

| Sprocket pitch radius (7.17) | ||

| T = 1925 X 7.17 X 1.5 = 20,700 IN. LBS. | ||

After determining the torque load, refer to table 3 to select the appropriate pin neck diameter. It shows 3/8-in. diameter pin neck will shear at 20,700 in. lbs.

To Order:

The part number for the appropriate Tork-Trol hub will be: 80A45 x 2-7/16 bore Tork-Trol hub will be: Tork-Trol Shear-Pin Hub Sprocket with a #25-2, Type A hub, Pin neck 3/8 in.

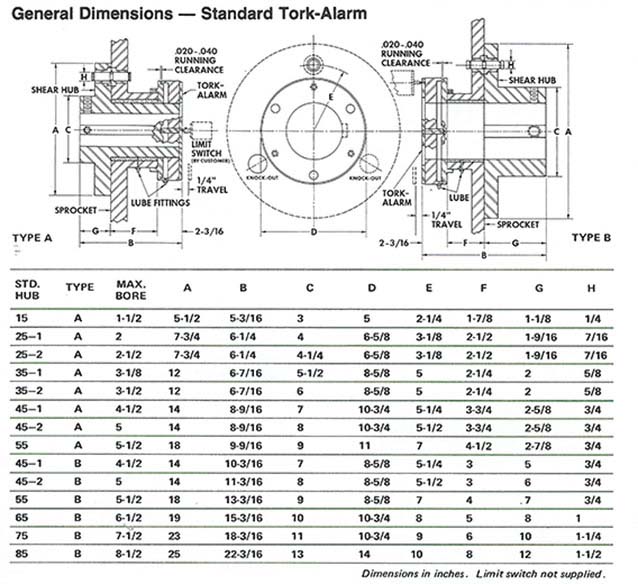

TORK-ALARM - Order Information - Dimensions