About Us

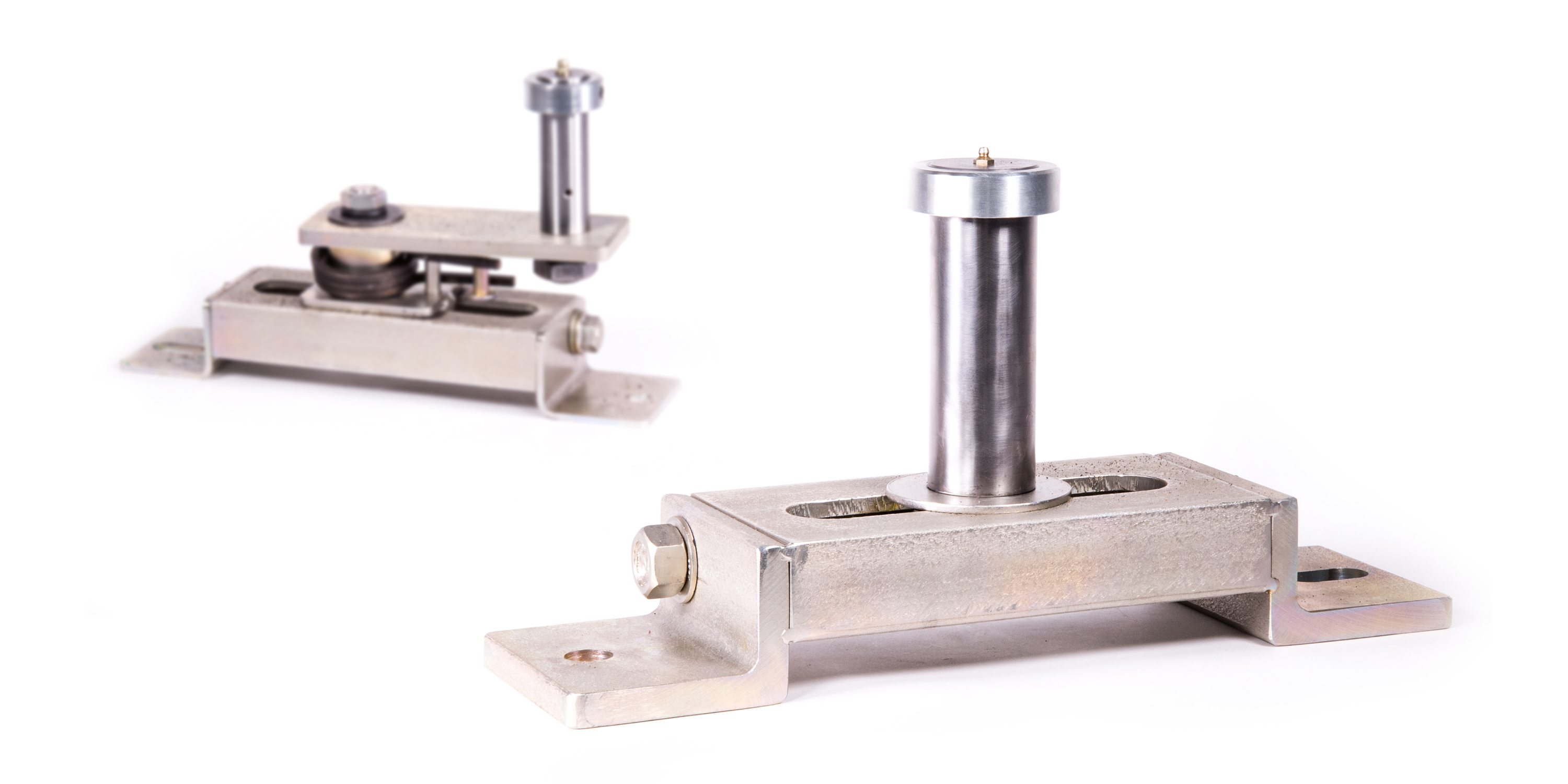

ABC MURRAY SPROCKETS now owns and manufactures the MURRAY TENSIONER line. MURRAY TENSIONERS have been manufactured and supplied for the POWER TRANSMISSION INDUSTRY since 1962. We are proud that our American Made products continue to provide the quality and dependability the MURRAY name is famous for.

If you have ever owned a Murray part you know that there is no better tensioner or sprocket on the market. Our dedicated team ensures that every part leaving our factory is built to the highest quality standards. Our website has the full range of our products from the Adjusto-Matic Tensioners to drive positioners and idle sprockets.

Feel free to browse the Specification section to learn more, then go to our Catalog to find the product that meets your needs!

specifications

INSTALLATION SUGGESTIONS

To complement the line of tensioners and positioners. Murray stocks a range of idlers for chain and belt drives. Special sizes and configurations can be furnished upon request. All idlers are fitted with shell needle bearings. Bronze bushings are available upon request.

- Tensioning that is too tight causes excessive wear on chain, belt and bearings.

- Tensioning that is too loose allows belt slippage or chain vibration, causing loss of horsepower or wear.

- Idlers should be located on the slack side of the drive chain or belt.

- The use of idlers on the back of V-belts causes reverse bend, and can reduce belt life. However, when inside idlers are used, the arc of contact is reduced and allowance must be made for horsepower loss.

- Chain idlers should be run on the outside of the chain.

- Idler sprockets should have at least three teeth engaged with the chain.

- Idlers, when used on the outside of the drive, should be located approximately 1/3 of the center distance from the small pulley or sprocket.

- Idlers, when used on the inside of the drive, should be located approximately 1/3 of the center distance from the large pulley or sprocket.