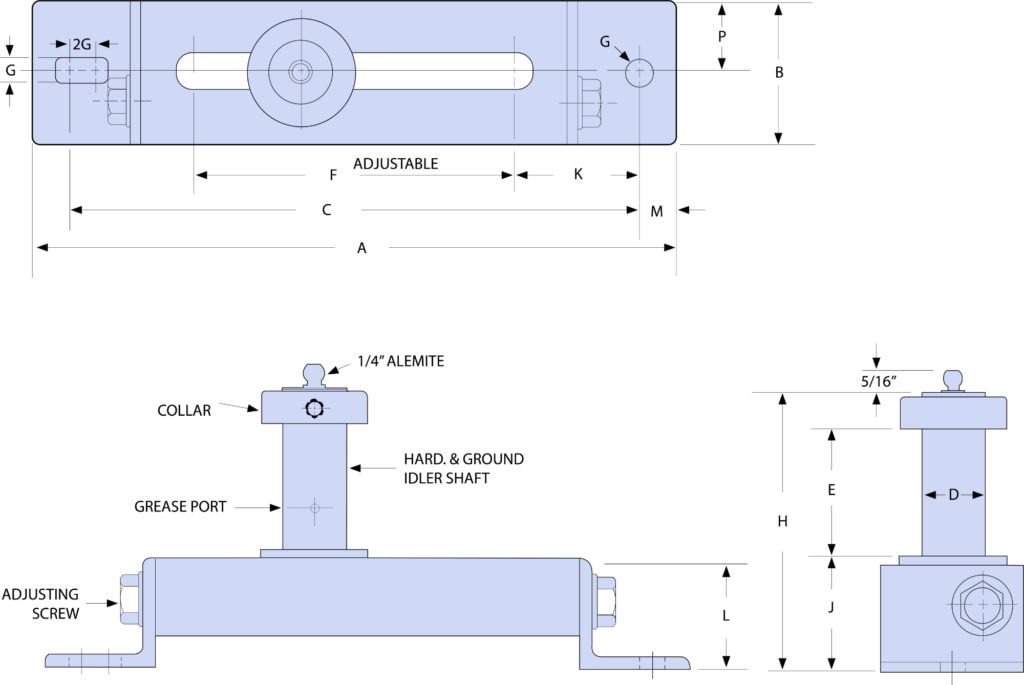

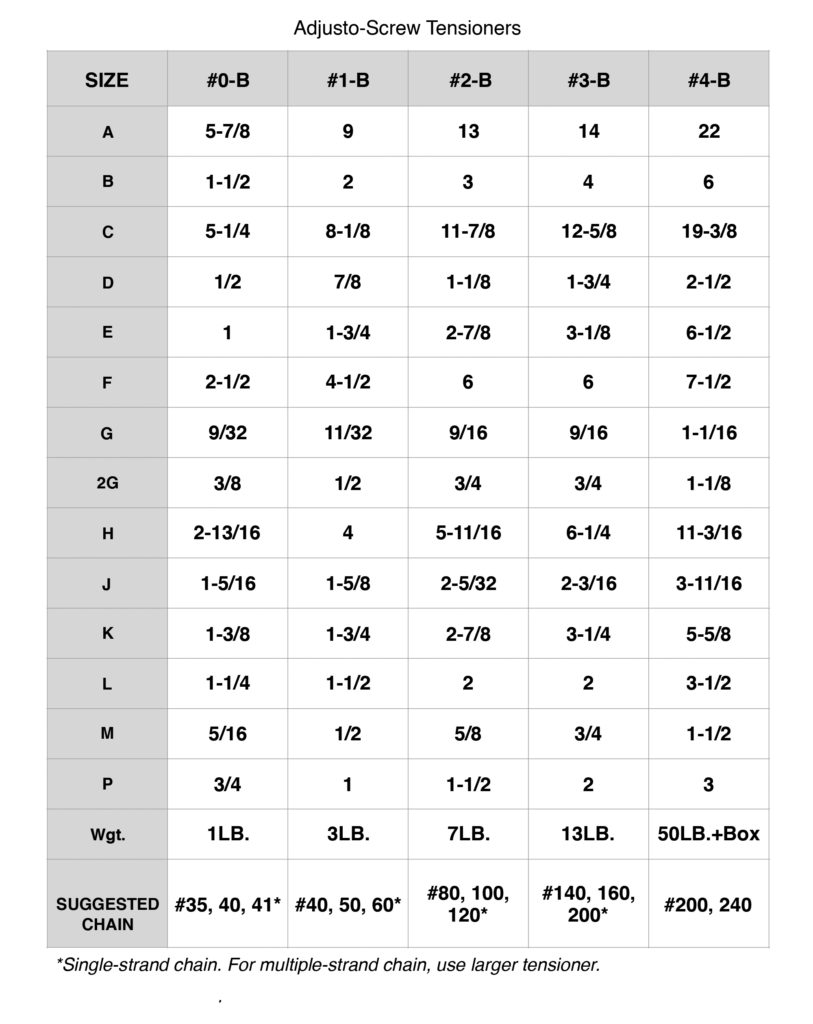

Murray Adjusto-Screw Tensioners

The Murray Adjusto-Screw, which is "slack-side" mounted, uses a screw to provide precise, easily-adjustable tension. The screw adjustment enables the user to set the precise tension necessary to provide maximum life for the sprocket and chain or belt. This is especially advantageous with heavy chains where slack is normally taken up by hand while making the adjustment. With the Adjusto-Screw, chain take-up and tension settings are both controlled with the screw. Adjusto-Screw tensioners are useful on vertical drives, preventing lower sprocket disengagement. Constructed of structural steel (many competitive brands use cast iron), this patented tensioner is available in a wide range of capacities capable of handling up to RC 240 roller chain.

Many drive systems are enclosed, for safety reasons. With conventional tensioners, the enclosure must be removed for drive adjustment. With Adjusto-Screw tensioner, tension adjustments can often be made through a hole in the enclosure adjacent the head of the screw, substantially reducing costly maintenance and drive down-time. The screw is adjustable from either end of the tensioner.

All Murray tensioners improve drive performance by eliminating whipping and slipping of loose drive chains and belts. They reduce vibration, noise and maintenance and provide additional life to drive components.

INSTALLATION SUGGESTIONS

- Tensioning that is too tight causes excessive wear on chain, belt and bearings.

- Tensioning that is too loose allows belt slippage or chain vibration, causing loss of horsepower or wear.

- Idlers should be located on the slack side of the drive chain or belt.

- The use of idlers on the back of V-belts causes reverse bend, and can reduce belt life. However, when inside idlers are used, the arc of contact is reduced and allowance must be made for horsepower loss.

- Chain idlers should be run on the outside of the chain.

- Idler sprockets should have at least three teeth engaged with the chain.

- Idlers, when used on the outside of the drive, should be located approximately 1/3 of the center distance from the small pulley or sprocket.

- Idlers, when used on the inside of the drive, should be located approximately 1/3 of the center distance from the large pulley or sprocket.