TORK-ALARM

TOR K-ALARM

Shear Pin Monitors, The Logical Companion For Tork-Trol Hubs: Here's Why . . .

• Instant Warning of Pin Failure

Tork-Alarm will sound a warning , or shut down a drive , within 10° of drive rotation after a pin shears .

• Unique Design

Unlike overload clutches or spring-detent devices , Tork-Alarm does not carry any part of the load. It can't wear out or change capacity with use.

• Mechanical Simplicity

Tork-Alarm is a rugged, all mechanical device , with a minimum number of parts . All-steel construction , with heat treatment where necessary for strength and wear resistance .

Elimination of complex mechanisms ensures optimum reliability.

• Complete Compatibility

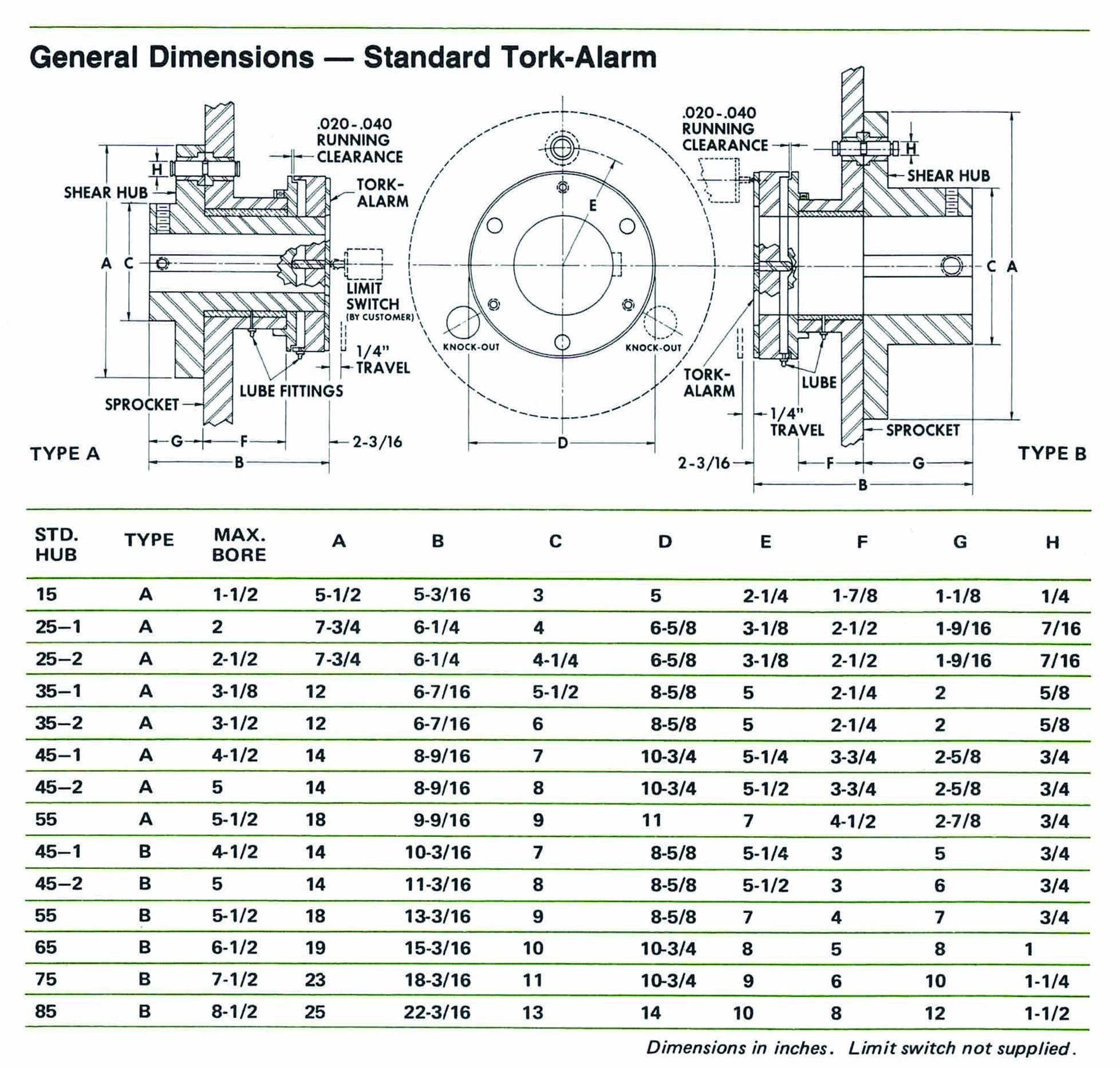

Can be used with any size or style Tork-Trol hub and sprocket. Basic design simplicity makes even special models economical.

• Remote Signaling Capability

You can monitor performance of hidden drives from a central station . Know instantly when a pin shears .

How Tork-Alarm Works

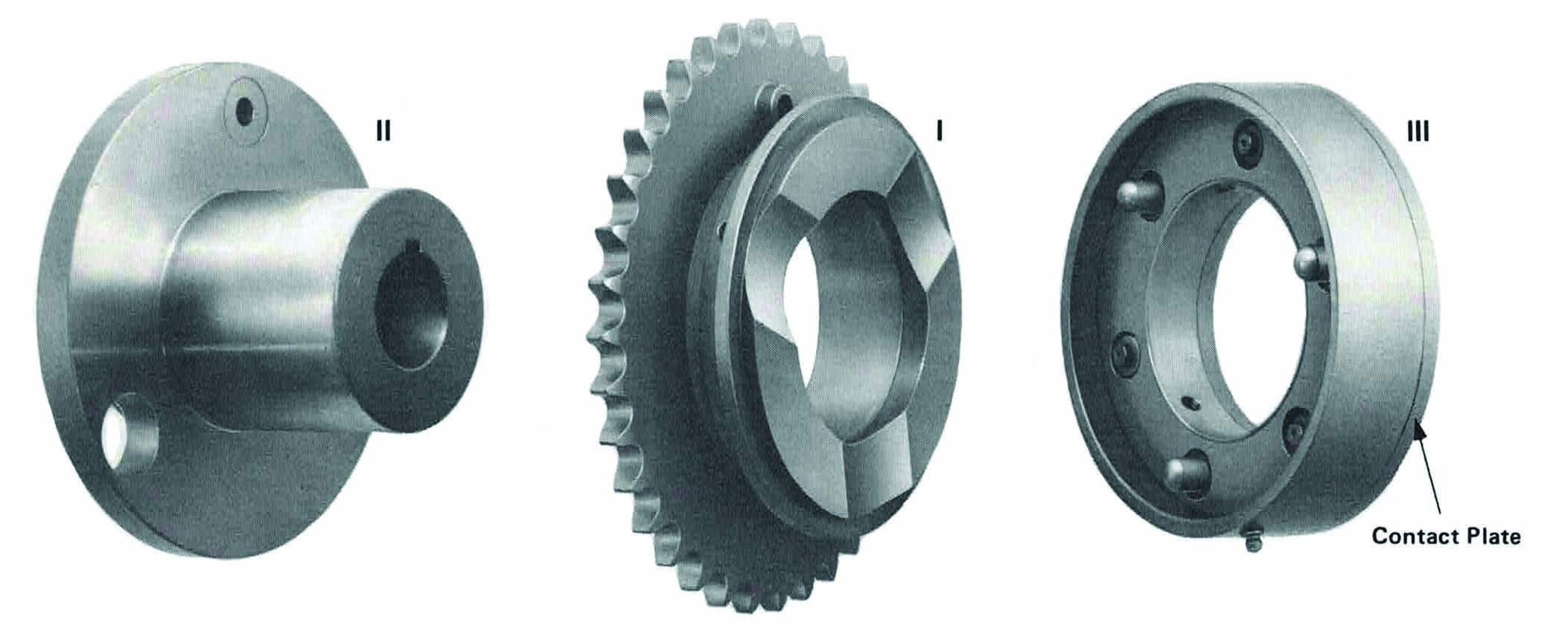

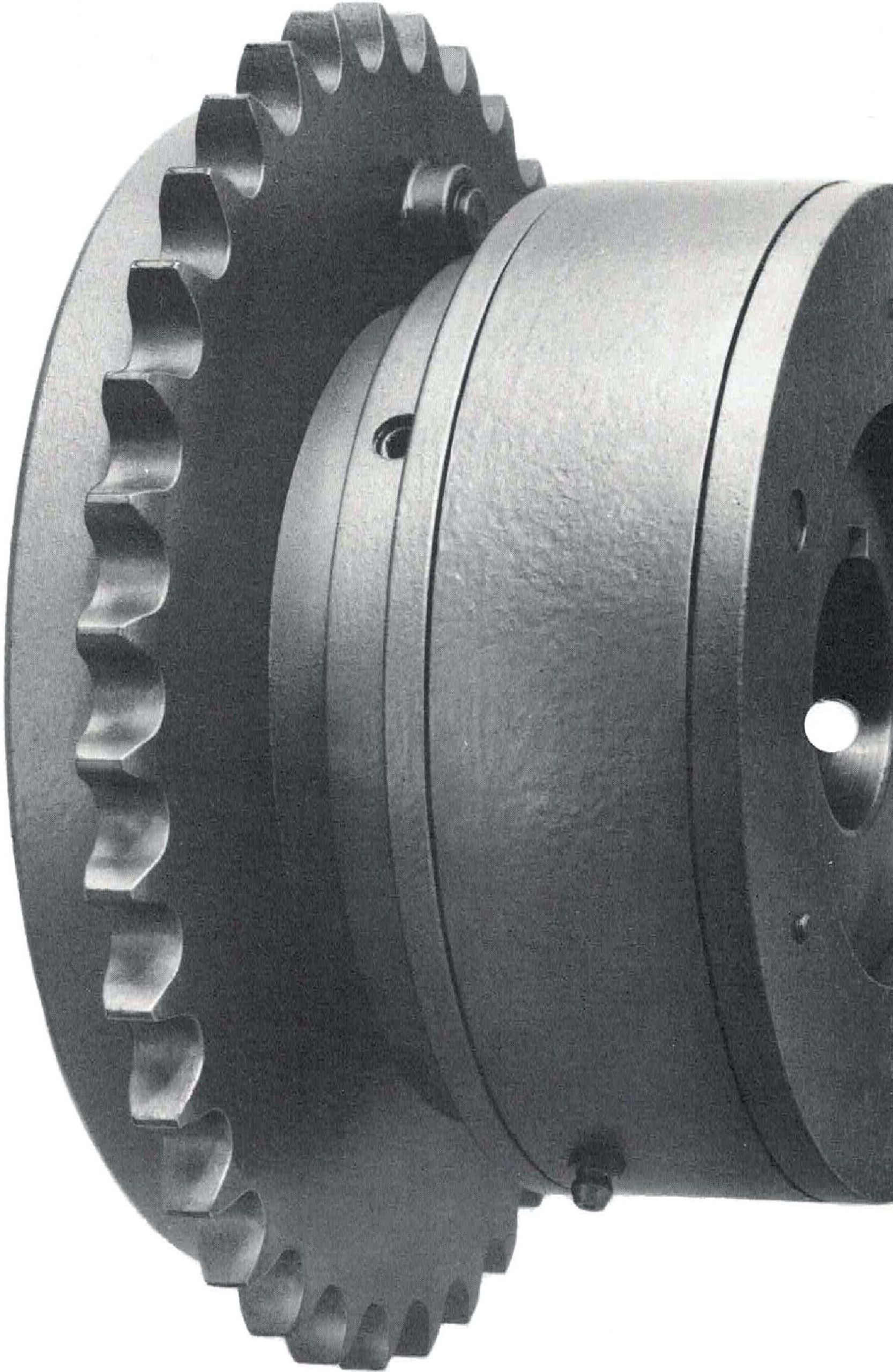

Part I is secured to the sprocket, Part II to the shaft. Part Ill, the Tork-Alarm mechanism, is attached to Part II or shaft, but has a contact plate that is free to move along the shaft axis. While the shear-pin is intact, all parts rotate together When a pin shears, Part I continues to rotate, but Parts II and Ill stop. Continued rotation of Part I forces cam pins attached to the contact plate out of their grooves, resulting in linear motion of the plate. This motion is used to trip a limit switch (not supplied) to sound an alarm or shut down the drive.