Tork-trol

Shear-Pin Hubs, Your Best Choice For Complete Protection: Here's Why . . .

• All-Steel Construction

Tork-Trol hubs are compact and strong . They take less space on the shaft and have higher torque ratings than cast iron or iron-on-steel hubs of similar size.

• Corrosion-Resistant Bronze Bushings

Hub sections that rotate when a pin shears are separated by a bronze bushing. They can't fret or corrode together . Breakaway torque is always uniform and repeatable .

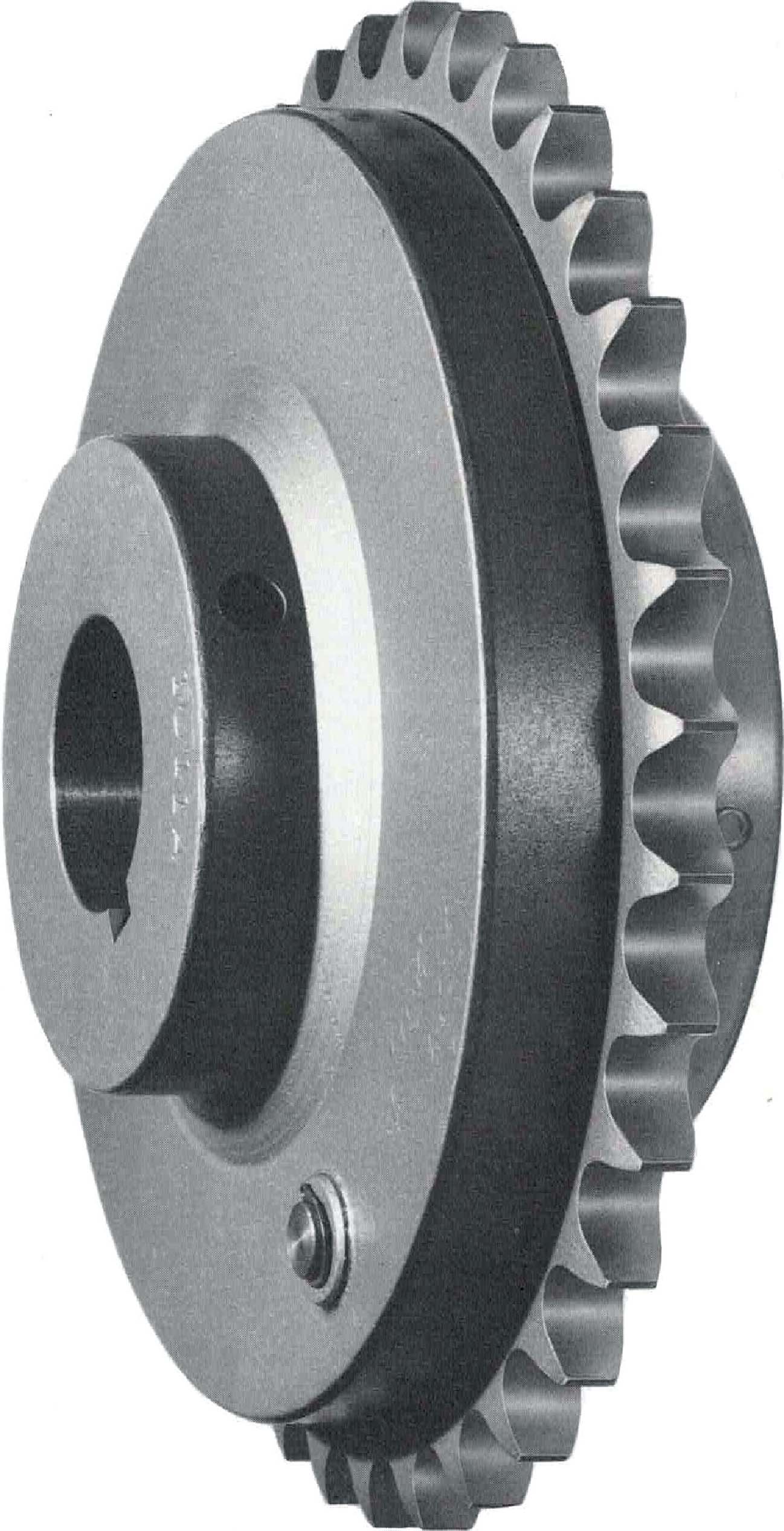

• Disc-Type Design

Pins are located in a solid steel disc , which is much stronger and more reliable than

"arm-type " designs . Disc-type design also makes it possible to provide multiple pin locations where desired.

• Pins Mounted In

Special Shear Bushings

Heat treated , sharp-edged shear bushings are press-fit at the head to provide a true shearing action . Pin bending, common with ordinary drill bushing equipped hubs, is minimized for more reliable operation .

• Welded Steel Sprockets

Standard construction on Tork-Trol hubs, eliminates the inherent problems of bolted sprockets . Hub and sprocket are welded together for maximum strength .

• Outstanding Versatility

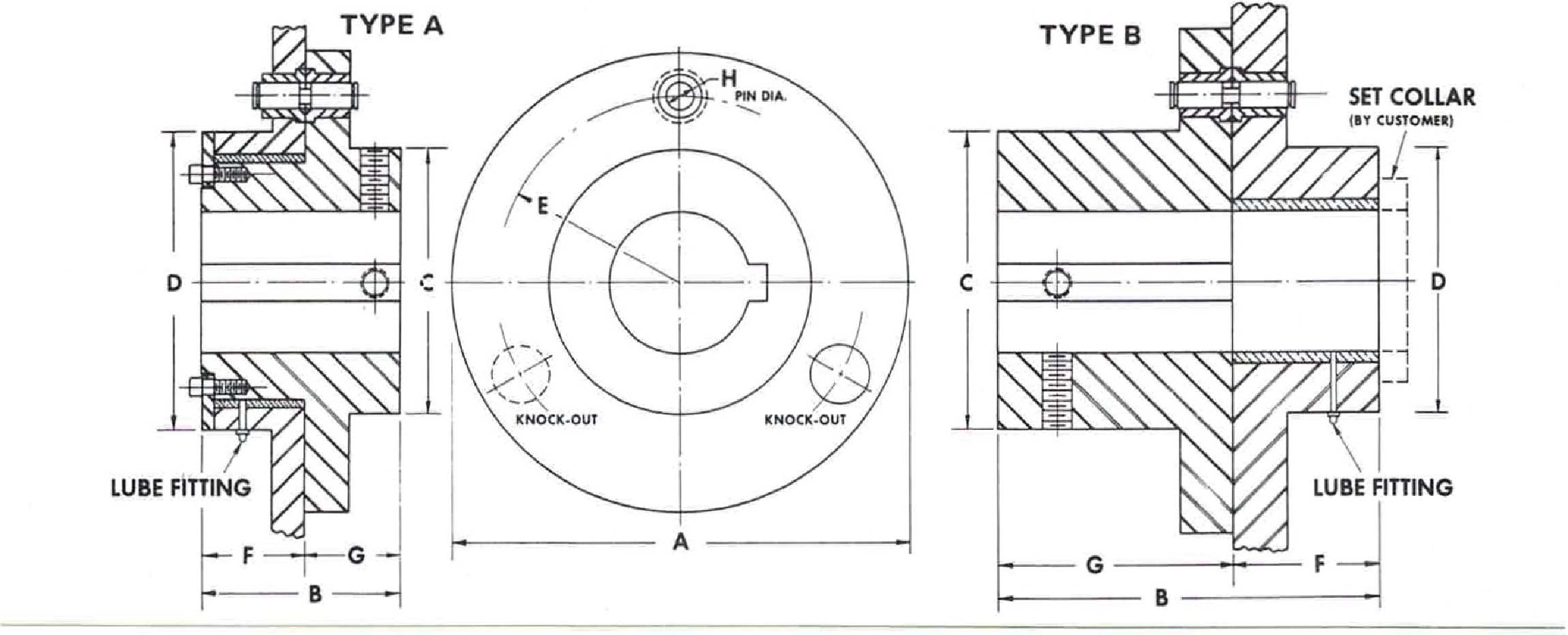

Two standard styles , and the widest range of stock sizes in the industry make Tork-Trol hubs your best choice for most applications . And , where a special hub is needed, Tork-Trol 's simple design makes modification quick and inexpensive .

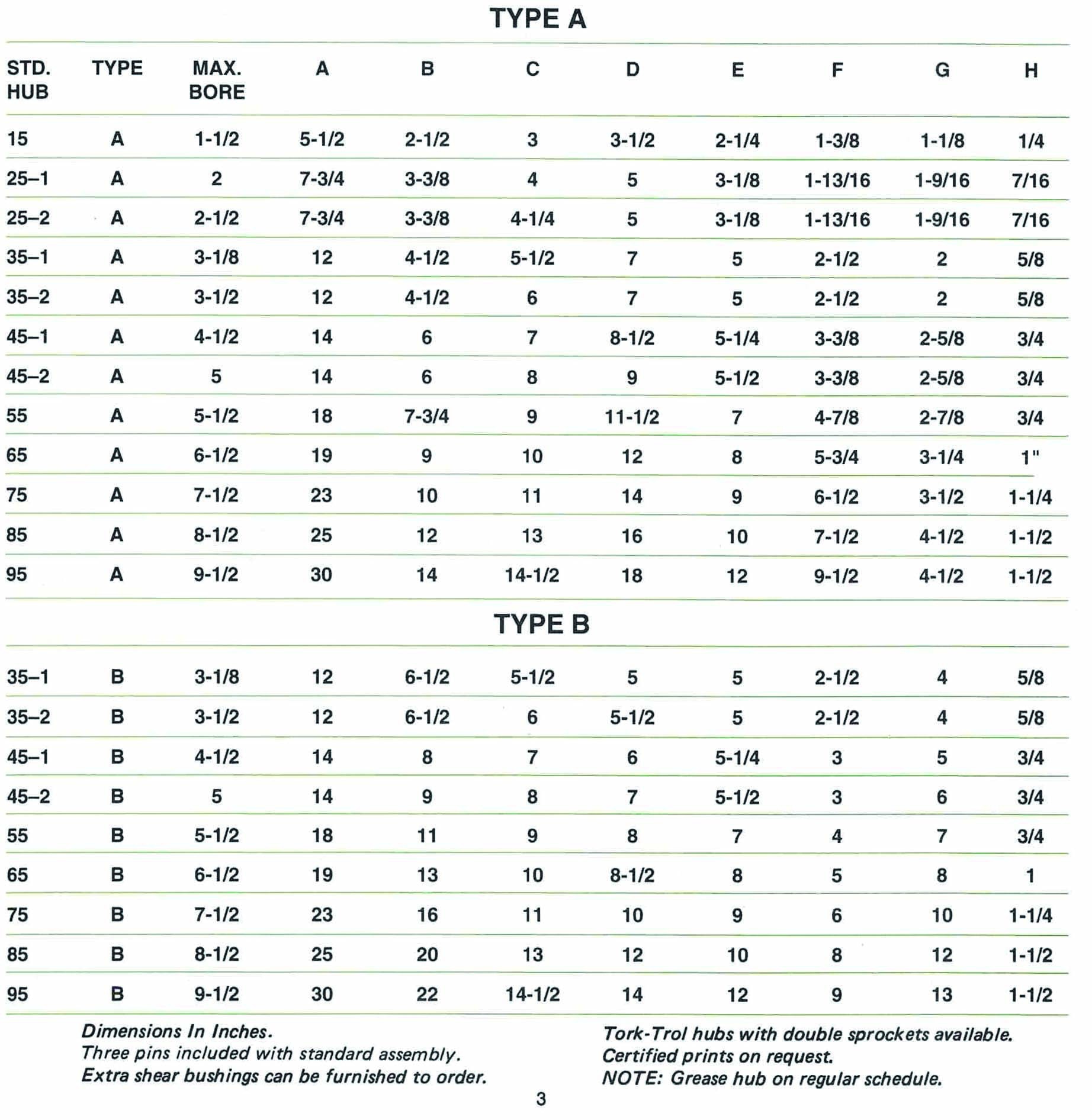

Tork-Trols are premium quality shear-pin hubs, designed to protect heavily loaded, slow-speed drives against damage from overloads and stalls. They are built in two styles with standard bore sizes from 7/8" to 9112'' . Larger bores available on request.

Use them with Murray's precision flame-cut steel conveyor sprockets, compensating drive sprockets , or roller chain sprockets , to build reliable , low-cost, shear-pin protected drives for your equipment. They combine the advantages of custom-built drives with the economy of standard , off-the-shelf components and the strength of all-steel construction .

Selection Procedure

Hub & Sprocket Size

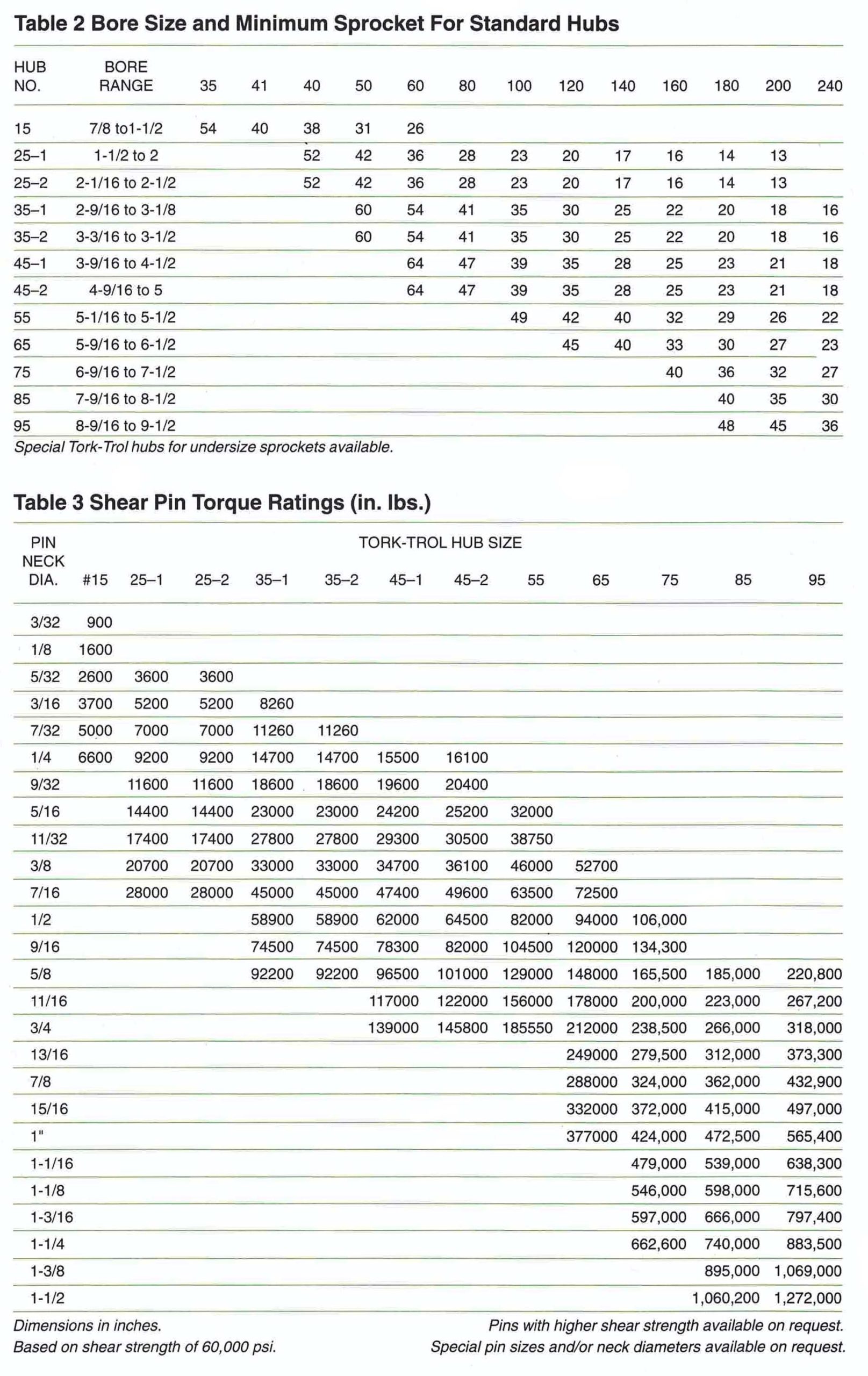

Hub size and the minimum number of teeth on the sprocket it carries are both related to shaft diameter . Refer to Table 2 to select the proper Tork-Trol hub to fit your shaft size , and then read the minimum number of teeth required on your roller chain sprocket , for that hub. If your sprocket has the minimum number of teeth or more, procede with the torque and pin neck diameter calculations below .

If your application involves a sprocket with fewer teeth than the minimum indicated in Table 2, Murray can probably provide a special Tork-Trol hub designed to accommodate it.

Other hub modifications are also possible to meet special needs. Consult your distributor or Murray's engineering department for assistance.

Torque Load

& Pin Neck Diameter

Use one of the three methods listed below to determine the torque load on the hub. Once the load is known, consult Table 3 and select an appropriate shear -pin neck diameter to carry it.

Symbols

T - Torque in inch pounds

HP - Horsepower at the sprocket RPM - Sprocket revolutions per minute

R - Sprocket pitch radius CP - Chain pullin pounds 1.5 - Starting load factor

Method A

When reducer output torque and drive speed ratio are known.

T= Output torque X

Drive Speed Ratio X 1.5

Method B

When horsepower at sprocket and sprocket RPM are known.

T= HP X 63000 X 1.5

RPM

Method C

When chain pull and sprocket pitch radius are known.

T= CP X R X 1.5

Selection Example

Select a Tork-Trol assembly for a conveyor chain drive:

Conveyor Requirements: Head shaft requires 5 HP at 22.8 RPM, with 1925 lbs. chain pull.

Conveyor sprocket pitch diameter is 14.334 in. and head shaft diameter is 2-7/16 in.

Drive Specifications: Motor; Reducer with 4600 in. lbs. torque output ; and 3:1 ratio chain drive consisting of RC80, 15-tooth and RC80

45-tooth sprockets. (Pitch diameter of RC80A45 sprocket is 14.334 in.).

Hub & Sprocket Size

Refer to Table 2: A #25-2 Tork-Trol hub will fit the 2-7/16 in. diameter head shaft. The

RC80A45 sprocket will fit the 25-2 hub and has more than the minimum number (28) of teeth .

Find Torque Load

& Pin Neck Diameter:

Method A

Known: Speed reducer output torque (4600 in. lbs.)

Speed ratio of chain drive (3:1)

|

T = 4600 x 45 x 1.5 = 20,700 in. lbs.

15

Method B

Known: Head shaft HP (5)

Sprocket RPM (22.8)

T = 5 x 63000 x 1.5 = 20,700 in. lbs

22.8

Method C

Known: Chain pull (1925 lbs.)

Sprocket pitch radius (7.17)

T = 1925 x 7.17 x 1.5 = 20,700 in. lbs.

After determining the torque load, refer to Table 3 to select the appropriate pin neck diameter.

It shows 3/8-in. diameter pin neck will shear at 20,700 in. lbs.

To Order:

The part number for the appropriate Tork-Trol hub will be: 80A45 x 2-7/16 bore Tork-Trol Shear-Pin Hub Sprocket with a #25-2, Type A hub, Pin neck 3/8-in.