tru-cut sprockets flame cut steel

TRU-CUT STEEL SPROCKETS - Why and How

Tru-Cut flame cut sprockets are more accurate, tougher and harder than cast tooth sprockets. Widely used with "Engineering-Class" chains for slow speed power trans mission and conveyor applications, these sprockets will also effectively and economically operate with ANSI roller chains (size RC #120 through RC #240).

TRU-CUT steel sprockets have many advantages

TRU-CUT SPROCKET SELECTION

I. SPROCKETS FOR STANDARD CHAINS, SPECIFY:

- Chain size (number marked on barrel or sidebar) .

- Number of teeth required.

- Bore, keyseat, setscrew .

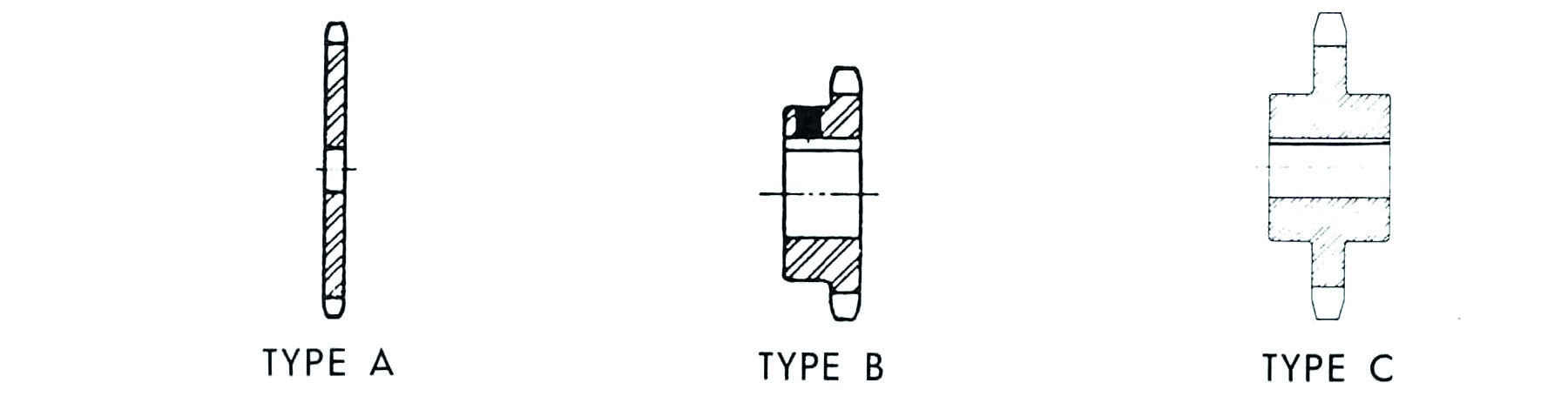

- Hub Type (B or C) see page 7 for minimum standard sizes.

- Hardness required (Rockwell C 30-35 is hardness as flame Rockwell C 47-55 is achieved with standard heat treating).

- Is sprocket one-piece or of split construction?

- Is bronze bushed bore required?

- If Type A plate-type sprocket (no hub), specify: - center hole ; bolt circle ; number and size of bolt holes .

- If minimum plain bore (stock bore) is required, specify ultimate or max imum bore required.

- Any special tooth contour (please supply print).

TO DETERMINE PITCH DIAMETER AND PLATE THICKNESS WHEN NOT KNOWN.

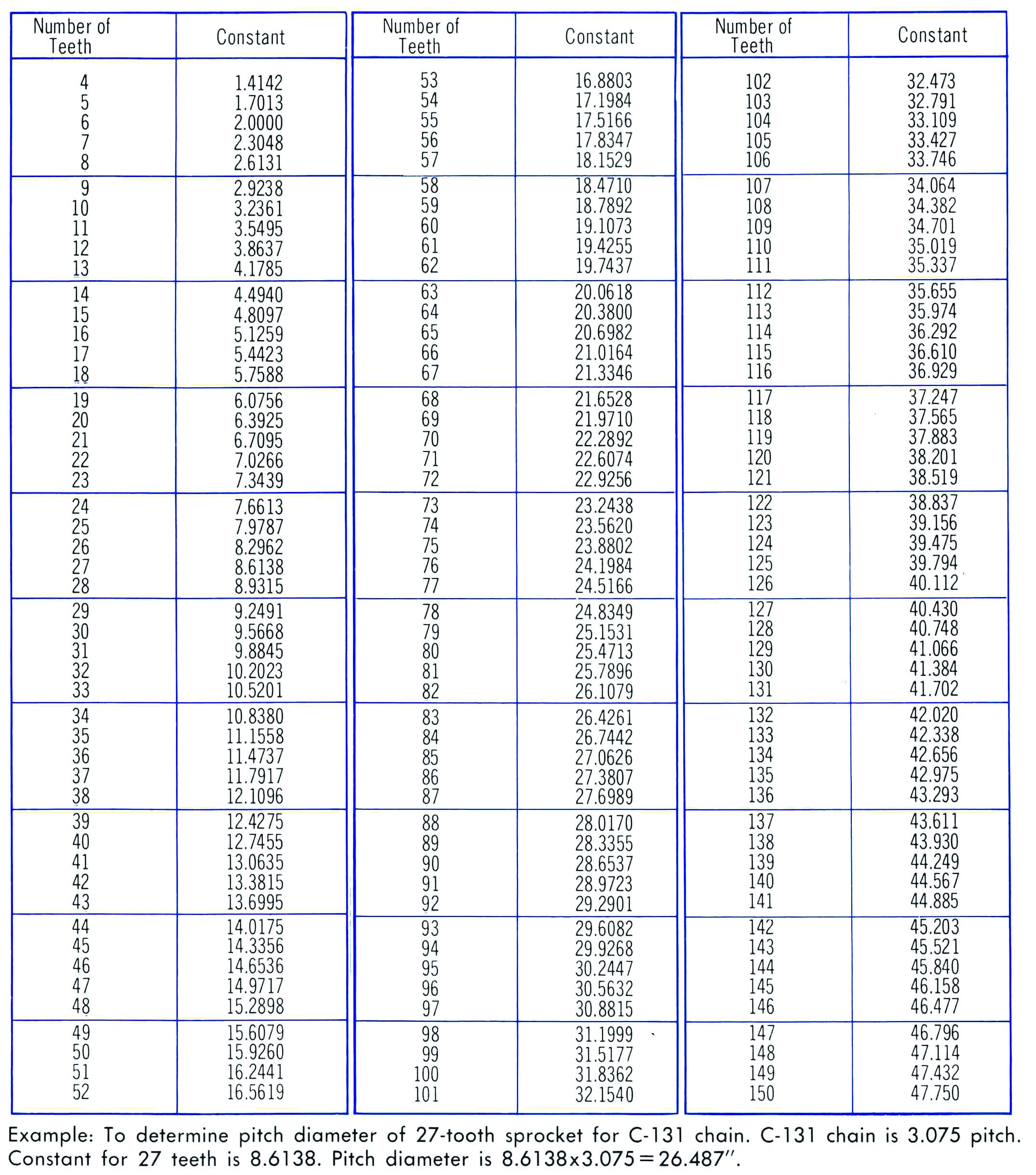

- To determine sprocket pitch diameter , multiply chain pitch by tooth constant shown in table on page 6. For Skip Tooth sprockets or Traction Wheels , use number of chain pitches on pitch diameter and not number of teeth.

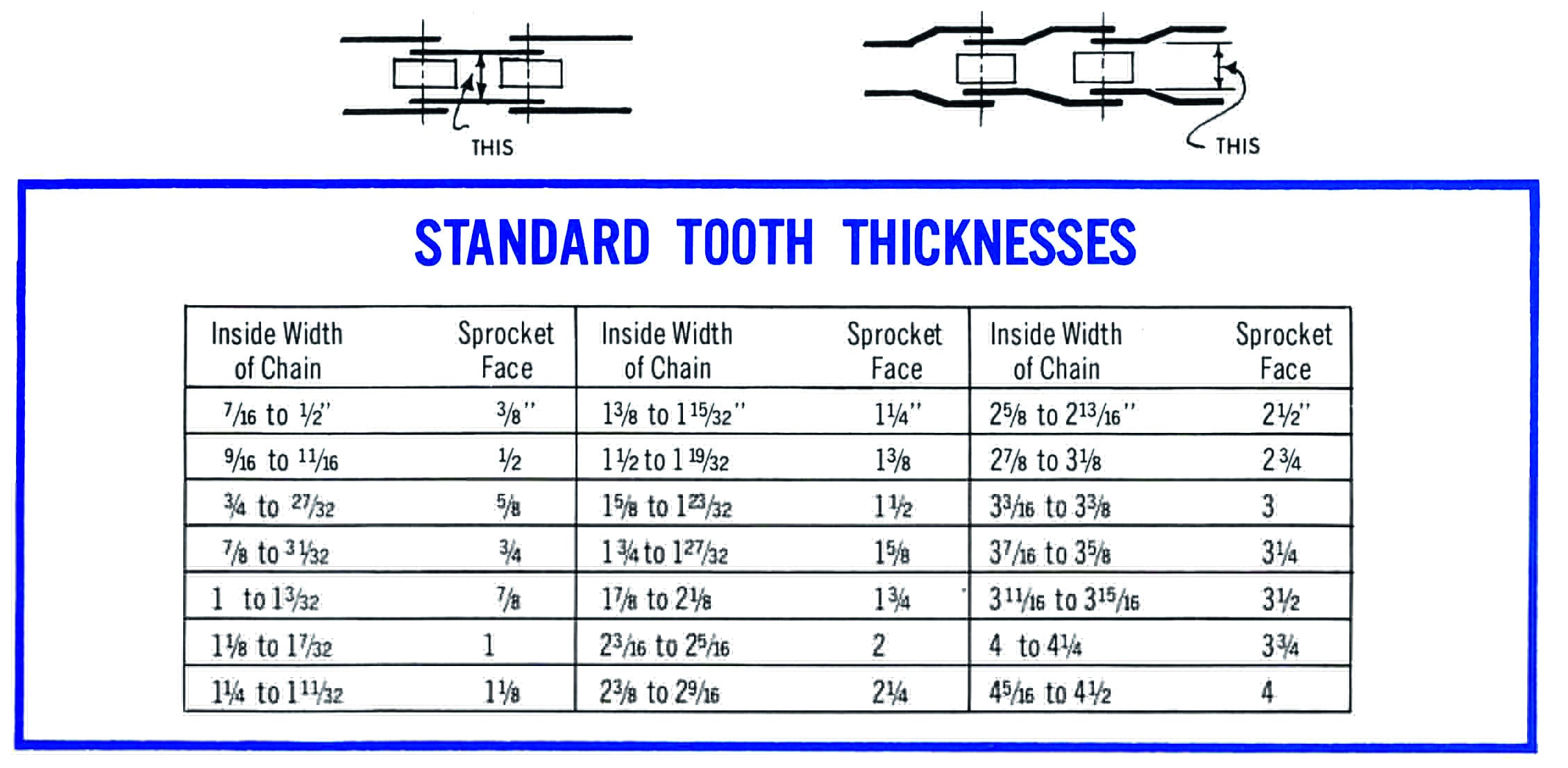

- Deter mine plate thickness fro m table and sk e tches below.

SPROCKETS FOR SPECIAL CHAINS:

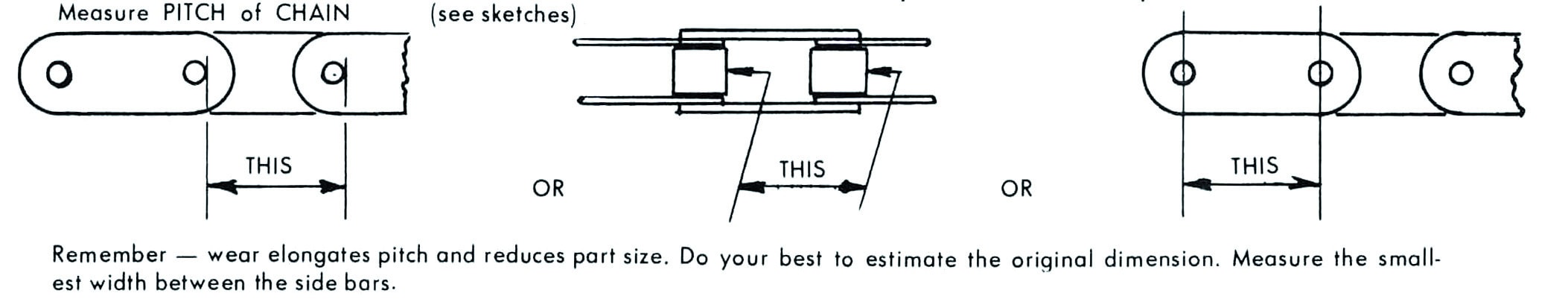

- In addition to all of the above information, it is necessary to determine pitch of chain:

- Measure roller diameter. If badly worn, try to determine original size.

- Measure height of chain side-bar.

- Is there any O.D. interference with chain attachments, guards, etc.?

- Are there rods or bars thru chain sidebars between the rollers? If so, please locate and list size of thru rods.

SPROCKET PITCH DIAMETER CONSTANTS

To obtain the pitch diameter of a sprocket, multiply the constant for the number of teeth from the table below by the chain pitch.

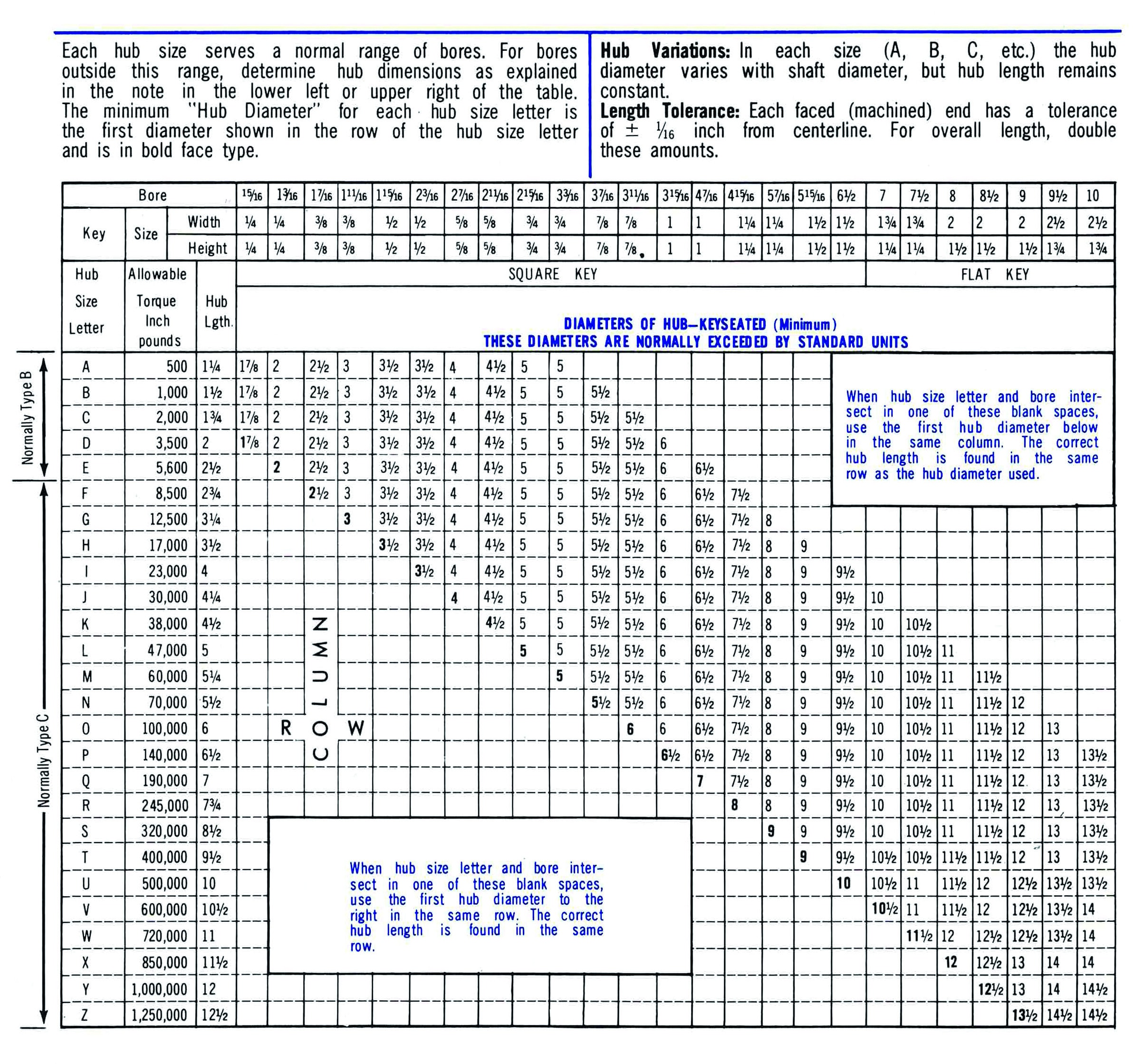

STANDARD HUB SIZES

FABRICATED STEEL